Silicon Carbide (SiC): Transforming Power Electronics

Silicon (Si, atomic number 14) and carbon (C, atomic number 6) combine to form silicon carbide (SiC), a wide-bandgap semiconductor. SiC’s bandgap (~3.26 eV) is nearly 3× larger than silicon’s, enabling devices that withstand higher electric fields and temperatures. This means SiC components (diodes and MOSFETs) can switch faster, handle higher voltages, and operate at much higher junction temperatures (often >200 °C) than silicon devices. In practice, SiC power devices allow power conversion systems to be smaller, cooler, and more efficient. Kotelectronic’s line of SiC Schottky diodes and SiC MOSFETs brings these advantages into EV, renewable energy, industrial, and other high-efficiency power designs.

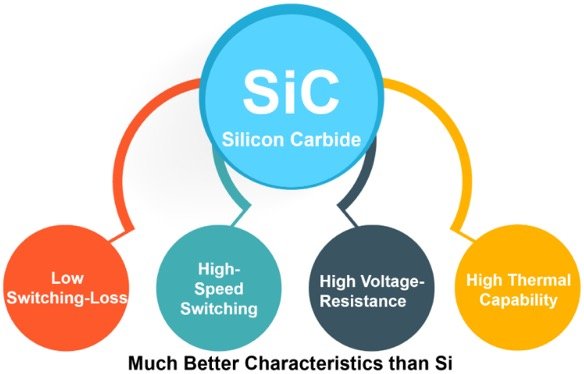

Advantages of SiC over Silicon

Much faster switching: SiC devices have much lower capacitances and higher carrier velocities than Si devices, allowing switching speeds 100–1000× faster. In practice, SiC MOSFETs switch rapidly with very low charge, dramatically reducing switching losses. Similarly, SiC Schottky diodes are majority-carrier devices with virtually zero reverse-recovery charge, so they turn off without large transient currents.

Superior thermal conductivity: SiC’s thermal conductivity is roughly 3× higher than silicon’s, and device structures are engineered to exploit this. Advanced SiC MOSFETs and diodes can operate with junction temperatures 250–300 °C or higher (vs. ~150 °C for Si). The excellent heat removal allows smaller heat sinks and simpler cooling, crucial in automotive and industrial environments.

Higher breakdown voltage and power density: SiC’s wide bandgap yields a much higher critical electric field (about 10× that of Si). This enables SiC diodes and MOSFETs with high voltage ratings (e.g. 650 V, 1200 V, 1700 V+) using thinner, lower-resistance drift regions. The result is lower on-resistance (RDS(on)) for a given voltage rating, improving conduction efficiency and robustness.

Lower losses and higher efficiency: SiC components have lower conduction and switching losses. Compared to silicon devices, SiC MOSFETs and diodes enable 10–20% system efficiency gains. In real-world systems, SiC Schottky diodes often provide ~2% higher efficiency and up to 33% higher power density versus Si designs.

Enhanced reliability: SiC devices are more robust under stress. The combination of higher breakdown strength and thermal margin means SiC MOSFETs are more resistant to thermal runaway and tolerate higher di/dt and dv/dt conditions. Likewise, SiC Schottky diodes can operate in parallel safely since their forward voltage rises with temperature, preventing “hot-spot” failure.

Kotelectronic’s SiC Product Offerings

Kotelectronic supplies a comprehensive range of LSDPS-brand SiC diodes and MOSFETs, designed for demanding power applications:

SiC Schottky Diodes: Fast SiC SBDs available in multiple voltage/current ratings (650 V, 1200 V) and package types for high-efficiency rectification.

SiC MOSFETs: High-voltage MOSFETs (650 V, 1200 V, 1700 V) featuring low RDS(on), fast switching, and robust reliability for power conversion and motor drive applications.

Each product page provides datasheets, package details, and ordering options. Kotelectronic continues to expand its SiC lineup to support next-generation energy and power systems.

Key Application Areas

SiC Schottky diodes and MOSFETs excel in high-efficiency, high-voltage applications, including:

Electric Vehicles (EVs) and Charging: For traction inverters, on-board chargers, and fast chargers, SiC devices deliver compact, efficient power conversion with reduced cooling needs.

Renewable Energy & Storage: Ideal for solar inverters, wind converters, and battery energy storage systems—where high voltage (600–1500 V) and efficiency are critical.

Industrial Power and Drives: Used in motor drives, robotics, UPS, and data center power modules for higher switching frequency and reduced system size.

Other High-Voltage Environments: Found in aerospace, telecom, and HVDC systems that demand high reliability and thermal tolerance.

Conclusion

Silicon carbide Schottky diodes and MOSFETs deliver clear advantages over silicon devices: faster switching, higher temperature capability, greater voltage endurance, and superior efficiency. For engineers and purchasing managers, this translates to smaller, cooler, and more reliable power systems.